Compressed Air Flow Measurement Meters

In most industrial facilities Compressed Dry Air (CDA) is a primary component of overall energy use. In fact, compressed air is considered to be the “fourth utility” after electricity, natural gas and water, and its cost is very often higher than the other three when compared by cost per delivered unit of energy.

Natural Gas Flow Measurement Meter

Thermal mass flow natural gas metering is a key tool. Natural gas is a fossil fuel composed of a mixture of hydrocarbon gases. The primary components are methane, ethane and propane. It is the cleanest burning fossil fuel, producing byproducts of mostly carbon dioxide and water vapor.

Wastewater & Aeration Basin Meters

Thermal mass flow wastewater & aeration basin meters area critical tool for municipal responsibility for these applications. The treatment of water and wastewater is a critical element of municipal responsibility. Increased public and private awareness of water quality, availability, and cost is a driving force behind the demands for better efficiency and economy in these processes.

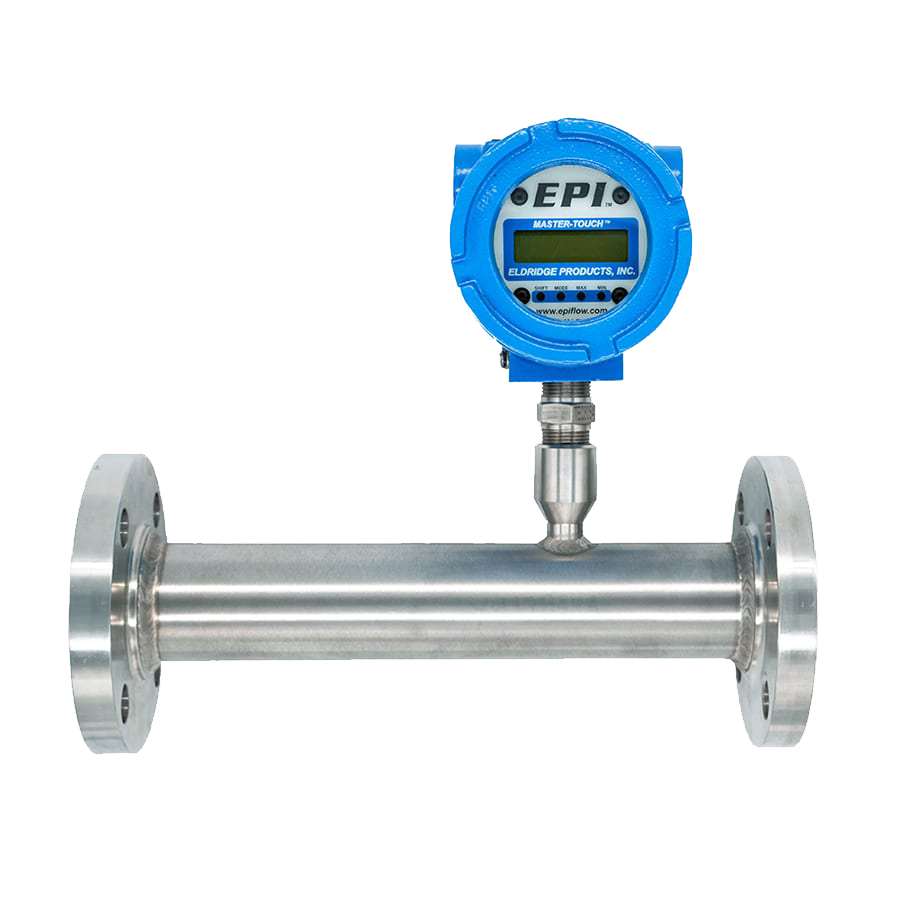

Flue Gas Applications

Generally speaking, Flue or Stack gas is the exhaust gas resulting from any source of combustion. Typical commercial sources of these gases are ovens, furnaces, boilers or steam generators and power plants. The need to accurately monitor, measure and report on the exhaust from commercial combustion systems is increasingly required by environmental regulations and the resulting company policies.

Flare Gas Applications

Various industries use vent and flare gas, such as wastewater treatment, landfills, refining, oil & gas, etc.. The flare is burning off waste gases to protect the environment and equipment. Thermal Mass Flow Meters are a good way for measuring that the flare system is operating as expected.